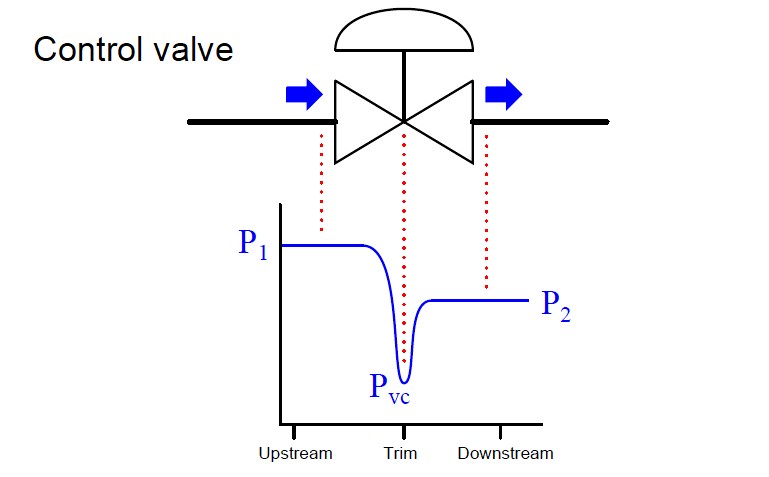

Flashing occurs when a liquid flows through a control valve and evaporates to retain the vapor. When the downstream pressure decreases to be equal to or lower than the steam pressure(P2<Pv), part of the liquid vaporizes to form a gas-liquid two-phase phenomenon, which is called flashing.

The danger of flashing

Under the condition of high-speed flow and pressure change, the liquid and the metal surface in contact will suffer cave corrosion damage, and the impact stress will cause surface fatigue damage.

1. Generate vibration and noise. When the bubble collapses, the liquid masses hit each other and also hit the metal surface, generating various frequencies of noise, which can cause the valve to vibrate when serious.

2. Reduces the performance of the valve. Cavitation produces many bubbles that block the flow path and limit the flow through the control valve, causing a significant reduction in the flow rate and regulation efficiency of the valve.

3. Damage the flow passage components. Due to mechanical and electrochemical corrosion, the metal materials are damaged and usually the parts damaged by cavitation are near the sealing surface. At the beginning of cavitation, pitting appears on the metal surface, followed by sponge-like, honeycomb-like traces on the surface; in serious cases, it can cause the valve spool to fall off, resulting in valve failure.

Since valves cannot prevent flashing, it is best to select valves with the appropriate geometry and materials to avoid or minimize damage.

Zhejiang Dongchen Valve Technology Co., LTD.

Previous:DOCN Flat Gate Valve